Global news

Position:Home > News > Global news

Stone wall construction process: hanging, hang wet

Date:2013-08-15 15:46 Click:

Stone wall construction process can be divided into three major categories : hanging , wet hanging , hanging wet hanging combination of technology , stone curtain wall construction is now used the most is hanging process .

Here the writer of these three different kinds of curtain wall technology for simple analysis,

Stone curtain wall technology:

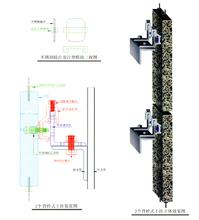

Hanging stone curtain wall construction technology

Hanging stone curtain wall construction technology

Dry hanging stone curtain Process Description:

Hanging stone exterior walls is a construction process, the process is the use of corrosion-resistant and corrosion resistant bolts flexible connectors, the marble, granite and other decorative stone directly linked to the outer surface of the building structure , stone and between the structure leaving a cavity 40 ~ 50mm . Finishes made using this process , the wind and seismic force of the amount of displacement allowed to generate in order to absorb part of the wind and seismic forces , without cracks and off. When the wind force disappears after the earthquake , but also with the structure of the stone reset. The process and the traditional wet process more jobs , eliminating the grouting process can shorten the construction cycle , reduce the weight of buildings , improve seismic performance, more importantly, to effectively prevent the filling of salt and other pigment stone penetration pollution, improve quality and perception of its decorative effect . The traditional means for the connection to grouting decorative panels , due to seasonal changes in outdoor temperature difference of expansion and contraction caused by the deformation of the outer facings , making decorative panels could fall off a threat to personal safety , by contrast, hanging stone of the construction process can be effective prevention of decorative panels off wounding accident. This process can also be panel mounted dry ornaments with glass walls or large windows , metal decking installation process and other supporting applications . Now many domestic large public building stone interior and exterior panel installation project take this hanging stone construction process .

Hanging stone curtain wall construction process:

I. Project Overview

× × Plaza, total construction area of 28000m2, basement, ground and 12 floors , with a total height 52.9m, is a collection of office , operating as one of the high-end integrated architecture.

The project was irregular pentagon , foreign inner circle , the East River length 74m, north-south width 56m, 59m, the whole building was in circular main facade, exterior decoration is mainly flat and garden cambered stone hanging wall .

Second, the construction techniques and construction methods

1 . Stone curtain wall installation process . Scaffolding erection → Measure , actinomycetes → steel skeleton production installation → stem pendant stone installation → Installation → clear seam sealant → finishing → Clean acceptance.

2 . Fu hand frame . According granite wall construction schedule , determined for each turn dismantle scaffolding erection of a three-tier , top-down construction, curtain wall construction to meet the operational requirements needed double erection of scaffolding outside their specific requirements:

1 . Double row inside the outer scaffolding pole from the wall 350 ∵ 400mm appropriate.

2 . To ensure the construction safety rules should be set up scaffolding Rachel points, but does not affect the granite slab installation, construction workers allowed to pull node except random crack , causing unstable structure .

3 . Scaffolding set up each step scaffold boards , baseboards , Body fences , retaining net.

4 . Scaffolding erection into line after inspection and acceptance do not meet the safety requirements of the site should be reinforced repair # .

5 . Scaffolding demolition: curtain wall construction has been completed, except before Scaffold crack should develop measures and operating workers for technical tests to ensure that the installed granite walls from damage.

Third, the construction machinery

The project site used construction equipment :

Welder three (60KVA)

Circular saw four (4KvA)

Size drill two sets (5KvA)

Portable cutting machine, milling machine four (6KvA)

Other electric tools ( approximately 8KVA)

Total power is : 83KvA, in order to ensure safe use of electricity , to avoid causing a short circuit Luanla wires , leakage, should be set up a dedicated line , a total distribution box .

Four , positioning actinomycetes .

Curved wall ( east side ) of the discharge line positioning is the key to good quality curtain wall project , reference should be part of civil structure construction on the arc discharge line checking procedures , positioning .

1 . Identify elevation ± 0.00 in the center layer and emit arc baseline ;

2 . Press the small cylinder centerline of sub-grid , the release segment control points ( each length is 1285 × 6 = 7710mm);

3 . With a theodolite ( or laser collimator ) will be invested in sub- layers of control points ; |

4 . The layers were measured with a spirit level horizontal level line ;

5 . In the main structure measuring, checking , based on a reference layer selected ( in elevation between ± O.00 ~ 46.8m ) , through keel installation, the distance from the wall properly adjusted , reduced vertical deviation indeed curved Luo vertical walls and circular degrees ;

6 . Customized within a 2m long arc measured by foot ( with its granite walls look the same radian ) check the operation at any time .

( Five ) steel frame column and beam installation.

1 . Keel installation.

Optional keel is:

Main keel 120 galvanized channel -

Second keel L75 × 50 × 6 galvanized angle

Connecting member w5 × 50 × 6, the length of galvanized angle L20mm

Anti fastener L75 × 50 × 6, a length of 70mm galvanized angle

Because this project uses wall stone hanging below the support member supporting manner . Therefore the main keel arranged vertically , horizontally arranged times keel . According to the keel line of position has been playing well , the main keel welded embedded in the wall plate. Considering temperature effects , the main keel on each floor 30mm slot, the vertical position of the column by a thin wire hanging drop hammer control, position alignment , the angle code and post weld . Column Installation error: before and after ± 2,0 mm, about ± 3.0mm, main keel welding is completed , in accordance with the second keel bomb put horizontal welding times keel, keel adjacent to two times the level of elevation error ? Lmm, within the full height 46.8m height } 10mm. Second keel construction is completed , according to the segmentation map and for supporting stone pendant quantity and anchor position, anti- fasteners welded sub-keel , all joints , welds require embalmed.

2 . Pendant mounting .

This project uses the Taiwan ILT aluminum tin alloy pendant, stone split according to size , using a large plate with a 4 per group ILT pendant support , to make four groups pendant together , when you install the first layer pendant , month horizon in each group ILT pendant transferred to a horizontal surface, and then tighten the fastener group connected with the anti- bolts , according to ILT pendant stone surface lines will be modulated onto a horizontal surface fastening , check and correct installation into line . -

Six , granite panel mount

Granite walls of the last decorative effect, project quality lies in the stone material and processing quality manufacturers , so the stone processing orders , be sure to send someone to processing factories and mines to see the quality of materials and processing blocks .

1 . Stone material requirements to adapt to climate change , anti- environmental pollution ( such as acid rain ) : Technical requirements and test methods to be complied with "natural granite stone building slab " (jC205-92). Compressive strength {250Mpa, density > 2560kg/m3, to ensure uniform color, no color , minerals have enough life of mine .

2 . Stone material processing is the key to control is the most prone to the problem areas . After processing the granite panels, required surface detail , color and luster , no impurities cracks , smooth cutting surface , dimensionally correct , no missing edge off angle , drilling and grooving smooth edges , no loose cracks.

3 . Before installation of granite plates each of its thickness should be , angle, color , etc to eliminate unqualified products , while avoiding excessive chromatic aberration , especially in the field of sheet metal processing , its slotted length, depth , location drilled strictly controlled. -

Seven , granite panel installation

1 . Granite panels installed hanging from the top down for each plate must have four fixed points, serious operation , and effectively " lift layers " ( ie, the weight of each piece of slate is transmitted only to the corresponding pendant, can not spread next stone on ) . -

Free . Good for every one stone shall be hung horizontally , vertically degree detection and overall curvature of the wall required match.

3 . Material requirements . Slab thickness of 25-30mm.

( This information is provided by Global walls exclusive finishing : http://www.umggwall.com)

Stone curtain wall technology needs point analysis :

A process

Primary treatment and installation of steel skeleton → decorative surface position actinomycetes , stone drilled or slotted → Install → Install pendant pendant → expansion bolt anchors and stone connection holes, slots, install decorative stone coating → → review and adjust the finishes stone location → with rubber or foam pieces filling seam and seam sealing silicone → finishes playing clean .

2 construction points

2.1 Primary treatment: steel skeleton in the wall layout , the horizontal angle must be welded to the vertical angle iron .

2.2 polystyrene board insulation installation: the angle between the keel and wall voids filled with sticky polymer mortar 30mm thick polystyrene board .

2.3 actinomycetes : according to design requirements pop up on the wall control network, from the center to both sides of the bomb release , should pop up the position of each plate line and the specific location of each pendant .

2.4 stone drilling or slotting : The pin-type hanger and hook type pendant , can be used on the impact of drilling holes in the stone . Blade hangs when using angle grinders available slots on the stone . To ensure that the hole , slot and reducing the accuracy of the stone is damaged, should use a special rack , fixed plates and rigs .

2.5 Expansion bolts : In accordance with the position of actinomycetes hit the wall expansion bolt holes , hole depth to slightly larger than the bolt sleeve length is appropriate. Fastening bolts and be buried , and finally with dynamometer testing coupling nut wrench tightening efforts.

2.6 pendant and stone installation : When installing bolts , while the right-angle plate fixation, and then install the anchor plate , stone underside of the upper and lower notch cut tank top gluing stone , stone in place , so that inserts into the upper and lower stone groove, adjust the position and tighten the plate bolts.

2.7 stuffer and closed seam : Stone After installation, has been checked , cleaned immediately after seam embedded rubber or foam pieces . Then hit pointing glue closed . Plastic injection should be uniform, glue joints should be smooth and full, also slightly concave on board . To ensure that both sides of the stone is not contaminated patchwork , patchwork shall affix adhesive tape on both sides of the stone protection , kick and then tear up the plastic .

2.8 wipe clean joints and finishes : stone installation is complete, remove all traces of gypsum slurry and I , with linen cleaned . According to the color of stone factory tune into paste caulking , clean edge fringe , with more dense uniform gap , clean color.

3 Points to note:

3.1 veneer stone plate varieties , corrosion , size , shape , flatness, geometric dimensions , finish, color and pattern must meet the design requirements, have product certification .

3.2 surface layer and the substrate should be installed firmly , hanging fittings of stainless steel, must meet the design requirements and national standards.

3.3 surface smooth and clean ; parquet correct , clear texture smooth, uniform color ; non entire board arrangement suitable site , yin and yang corner of the plate to the right .

3.4 seam uniform grid , slab smooth, dense caulking seams , the same width , no dislocation , dislocation.

3.5 prominence around the board to take the entire board sleeve cut , accurate size , edge anastomosis neat, smooth, dado, cheek and so catchy straight.

3.6 material is strictly prohibited in the handling and operation of pollution by mortar and other dirt , wipe promptly if contaminated . Also to prevent salts chemicals , nonferrous metals and other direct contact with the liquid caused the stone surface contamination.

3.7 ensure smooth paste face mouth .

4 stone plate Tolerance Project :

No. Item Tolerance (mm) inspection methods

A vertical plane perpendicular to two with 2m care line inspection plates and measuring tape

2 smooth surface with a 2m by foot and feeler

3 with a positive angle Founder two feet and feeler

4 seams straight two pull cords and measuring tape pass inspection

5 dado catchy straight two pull cords and measuring tape pass inspection

6 seams level 0.3 with steel ruler and feeler

7 joint width 5m small deviation 0.5 pull cord and a measuring tape checking

5 product protection

5.1 should be installed slate practical and reliable anti-pollution measures ; should promptly wiping left in the door window frames, glass and metal finishes plate dirt, especially when gluing joints on both sides should be pasted in the rubber protective film to prevent pollution ;

5.2 veneer finish live on , easy to bump the edges and corners to do the work product protection , other types of operation shall not scratched and chipped stone .

5.3 Chaigai shelves and on the material , be careful not to bump hanging stone veneer ;

5.4 Construction does not meet the strength epoxy adhesive shall not carry out a layer of construction , and to prevent shock and vibration ;

6 should pay attention to the problems

6.1 decking surface uneven color : The main reason is no try spell before construction , number and carefully selected ;

6.2 line angle not straight seam grid uneven wall is not flat :

Mainly due to the pre-construction not seriously checked in accordance with the actual structure size drawings for the keel welding position is not accurate, not seriously checked by processing incoming paper size dimensions , processing incorrect size , construction , etc., causing improper operation . Line angle not straight seam cells respond to the problem of uneven material stringent approach to check substandard materials shall not be used ; line angle is not straight, the wall is not flat through the construction process should strengthen inspection to be corrected .

6.3 Wall pollution : when gluing pointing stick tape or tape is not falling, not timely after gluing pollution to clean up the pollution caused by the wall , use a knife or ax for scrape . To the top down before the completion of a thorough cleaning scrub ;

6.4 at height should follow the " construction work at heights safety technical specifications " (JGJ80-91) with the relevant provisions ; scaffolding erection shall comply with the relevant regulatory requirements. Site electricity should follow the " construction site temporary electrical safety specifications " (JGJ46-88) the relevant regulations.

Specification See also:

1 . " Building walls " (JGJ3035-1996)

2 . " Metal and stone curtain wall engineering and technical norms " (JGJ133-2001)

3 . " Hanging stone curtain wall with epoxy adhesive " (JC887-2001)

4 . " Curtain wall construction quality testing standards " (JGJ/T139-2001)

5 . " Curtain wall construction quality acceptance criteria " (GB50210)

6 . " Code for Fire Protection Design of Tall Buildings " (GB50045-95)

7 . " Anti-mine capability building walls shake table test methods " (GB/T1857)

8 . " Building walls physics analysis " (GB/T18/15225)

9 . " After the wind building curtain wall deformation performance test methods " (GB/15226)

10 . " Building walls rainwater infiltration performance test methods " (GB/15228)

11 . " Building walls air permeability test methods " (GB/15227)

12 . " Classification of natural stone products radiation control standards " (JC158-1993)

13 . " Hanging decorative stone and metal pendant " (JC830.1-830.2)

Wet hanging stone curtain wall construction technology

Wet hanging stone curtain wall construction technology

Also known as curtain walls hang wet wet paste is cooked grouting method known construction , cement mortar is used as a bonding agent will be secured to the building structure stone decoration on the construction method .

The stone works according to design requirements using wet paste the entire board construction technology, construction difficult , the construction should first try stickers, meet the requirements before the process cards in full swing operation.

First, the material preparation and stone processing

Quality stone used in this project must meet the design requirements and national norms. Stone samples once the owners , designers confirm sealed samples , should be strictly in accordance with the provisions of procurement preparation, the same variety of stone mining should be a single source of purchase . This works with stone manufacturing and processing have advanced equipment and technology. Other shop materials ( cement, sand , binders , pigments , detergents , waxes, various anchors , embedded parts , support , etc. ) are required preparation or processing should be designed .

Second, the construction preparation

1, the detection grassroots structures do construction large drawing

Various stone finishes installation, should be based on the design drawings on the stone base structure installation position measurement checks on various substrates vertical flatness , spacing , design requirements , etc. measured slope verification of difficult construction construction of mosaics to do large drawing , drawing a big sample plate arrangement drawing .

2, the primary treatment

According to the measurement test results conducted on the grass trimmed , smooth base surface should be done hair, obviously concave surface at the grassroots level , the application of 1:3 cement mortar , primary surface remnants of mortar, dust , paint, etc. should be cleared of dry static . To make leveling layer , in order to enable the grassroots with the leveling layer firmly bonded , you can wipe the spill before leveling layer of cement slurry polymerization .

3 , Surveying

A variety of stone paving must design layout before construction of large drawing diagrams or conduct site surveys actinomycetes , pop and horizontal centerline elevation lines and sub- grid.

4 , palettes , pre-fight , Arranging

This works with stone layout diagram should be based on a good finished products processing factories are numbered packaging after unpacking stone approach should first be checked by block will be broken, missing edge off angle all singled out as a separate pile , and notify the reprocessing plant . In the palette based on on-site inspection a good pre-fight , make up and down through the pre-fight more consistent color pattern , texture smooth, tight joints fit . Pre-fight good stone to bidirectional number, and then classified with stacked vertical stand .

Three , wall stone installation ( exclusive of this information by Universal wall finishing : http://www.umggwall.com)

1 , the construction process

At the grassroots level in accordance with the design requirements previously perforated surface , buried expansion bolts or hardwood wedge wire fixed to the hole . Decorative panels installed before the first drill bit according to the design requirements of 5mm diameter with a pivotal hole , the copper wire penetration hole. Plates before installation , you should first check the grassroots level conditions, such as excessive unevenness should first deal with leveling or chipping . Before installation in accordance with the prior horizontal and vertical lines to find a good pre- row, and then in the next row two with the most plate leveling looking straight , up the dash , and then start from the middle or the end of the installation . And use copper wire to the surface of the plate and the structure embedded bolts lashing , and pay attention by using drag strip straight by flat , to ensure smooth corners junction board and the board . The gap between the plates with the primary ( i.e. filling thickness) , the design requirements , is generally 20-50mm. Decorative plates installed, paste paper or fixed gap plugging the bottom and both sides strict cream with a fixed upper and lower mouth temporarily fixed , the larger the plate fixed to add support. After fixation with 1:2.5 cement mortar grouting layering until the distance catchy 50-100mm stopped. Then paste catchy temporarily fixed fixed tick off Clean up the gap , and then install the second line sheet, so fixed in order from bottom to top , grouting. All Sheet After installation, clean the surface , and then use the same colors and sheet caulking cement mortar , while wiping edge inlay , inlay paste the gap dense color. Plates have been contaminated after construction surface dull , so be certain fastness maintenance should be performed after re- porcelain waxing.

2, Technical Requirements and Measures

Veneer joint width should meet the design requirements. Decorative panel installation should hang straight alignment , joint width can be adjusted cushion wedge and shall ensure that the outer surface of the flat, vertical and board catchy Junpei . Grouting , should be watered and decorative panels on the back surface of the substrate moist, then layered perfusion mortar , each filling height 150-200mm, maximum height shall not exceed the board 's 1/ 3 , mortar application of small steel rods inserted pound dense, pending after its initial setting , you should check the board position , such as mobile dislocation should be removed reinstalled. Construction joints should remain in horizontal joints decorative panels at the following 50-100mm . Winter construction , the use of mortar shall not be less than 5 degrees Celsius and humidity . Hardened mortar , freezing measures should be taken .

Finally a cross between wet hanging hanging wall between the construction process:

Both processes have wet hanging hanging stone curtain wall construction plan process

Stone walls wet paste , divided into two kinds , one is wet hanging , also known as wet paste . One is thin , the direct use of cement or pure mud paste . Specifications are similar .